We recently had the opportunity to visit insulated water bottle manufacturing factory, where we were able to witness firsthand the impressive results of their digital transformation efforts. The event, themed “Industry 4.0”, provided an insightful look into the factory’s production line and how it has been transformed through the integration of advanced technology.

KingStar is the leading stainless steel insulation drinkware manufacturer in China, with its headquarters located in Shanghai and a factory situated in Jinhua, Zhejiang province. The company boasts a modern production base that covers an area of 30,000 square meters and employs over 900 staff members. KingStar specializes in producing a wide range of products such as high-quality stainless steel water bottles, lunch boxes, dog bowls, tumblers, cool caners, soap dispensers beer glowers and so on. The company’s focus on quality and innovation has earned it a reputation for producing high-quality products that are both durable and stylish. This manufacturer also collaborates with many well-known brands to provide customization and co-branded gift services. This approach allows the company to cater to the diverse needs of its customers while also expanding its reach in the market.

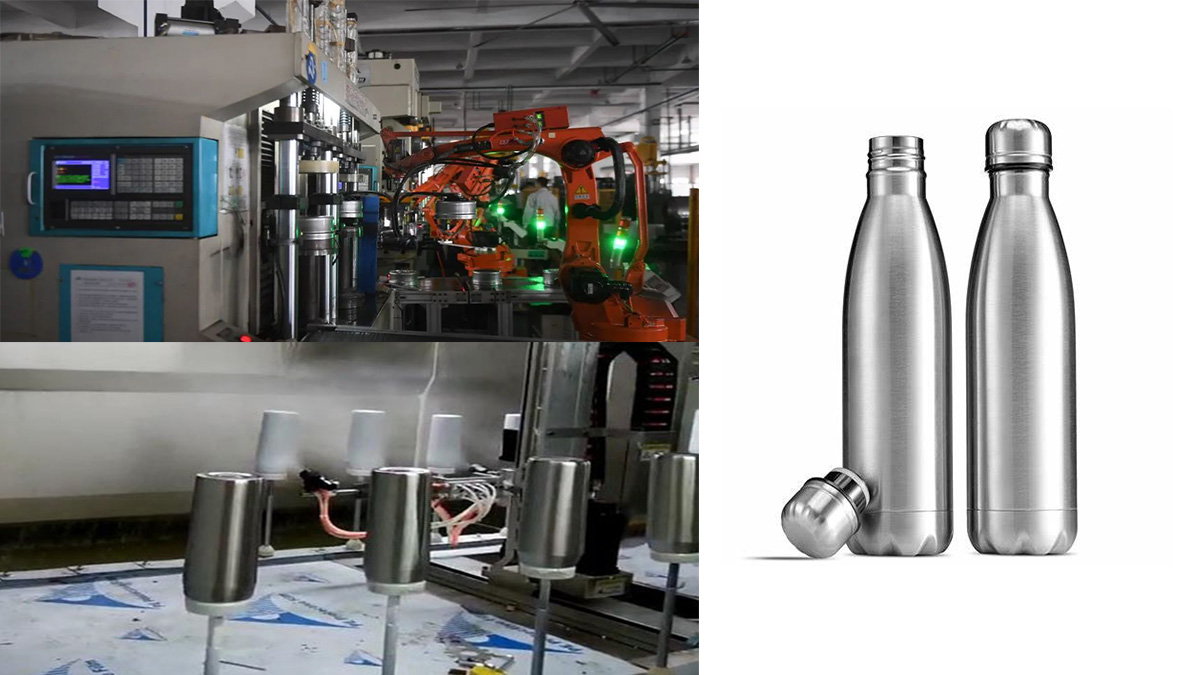

Following KingStar’s director, our team came to KingStar factory in Jinhua, Zhejiang province. This visit allowed us to witness firsthand the implementation of Industry 4.0 practices at KingStar. As soon as we entered the factory, we were greeted by rows of machines operating smoothly on the production line. AGV (Automated Guided Vehicle) transporters were automatically moving goods, while mechanical arms and stacking machines were working in an orderly manner. Sky robots were picking up product parts for unmanned operations and the Carbon Cloud platform was displaying real-time energy consumption data. The 30,000 square meter factory was bustling with activity, with processes such as tube cutting, segmentation, welding, electrolysis, polishing, laser engraving and assembly all taking place seamlessly. Every step of the production process was accompanied by a display screen or workstation.

These screens displayed real-time data on production status, equipment operation and order delivery. Behind each screen were sensors and edge servers connected to various production control and management software systems that served as the “central nervous system” driving the entire smart factory. This technology enabled KingStar to transition from traditional manufacturing to intelligent manufacturing, leading the way in high-end manufacturing. It is clear that KingStar is committed to staying at the forefront of industry innovation and implementing advanced technologies to improve efficiency and productivity in their manufacturing processes of Industry 4.0.

KingStar manager told us, “We are grateful for the advancements in 5G Internet technology that have enabled us to transition towards smart manufacturing and embrace Industry 4.0 practices within our factory. Recognizing the unique challenges faced by the drinkware industry, which involves both formula processes and process assembly, as well as a diverse range of products, our team has collaborated closely with China Mobile to create a cutting-edge 5G smart factory. This partnership has allowed us to leverage a specialized network model that ensures seamless information flow, a stable system and precise operational control throughout the entire Industry 4.0 manufacturing process.”

Then he added that KingStar plans to establish an industry 4.0 model factory within the sector. This initiative will involve the extensive application of cutting-edge technologies such as big data, cloud computing and artificial intelligence. By leveraging the power of an industrial internet platform, KingStar aims to integrate and control the entire process of business operations, thereby achieving full automation, informationization of the entire field and intelligent connectivity throughout the logistics chain. In order to streamline material circulation, KingStar will utilize advanced equipment such as automated guided vehicles (AVG), rail guided vehicles (RGV), logistics lines and robotics to implement a non-landing production mode for logistics. This innovative approach will significantly enhance efficiency and reduce operational costs. Furthermore, KingStar will also employ the 5G carbon cloud platform as a foundation for comprehensive energy, environmental protection and safety management. By implementing this platform, the company will be able to achieve remarkable results in terms of energy conservation and emission reduction, contributing to a more sustainable future for the industry.

In a recent discussion, the manager also highlighted the importance of digital transformation in the production lines of drinkware and food container products. The core of this transformation lies in intelligent manufacturing, with deep integration of industrial software being the key to success. KingStar has already established a comprehensive product intelligent production line system that encompasses various aspects of modern manufacturing. From industrial internet of things (IoT) to intelligent factory management and enterprise business management, KingStar has developed a new generation of networked collaborative manufacturing platform. This platform covers all levels of the enterprise, including the enterprise layer, factory layer, edge layer and device layer. It integrates critical applications in various domains such as digital supply chain, production and manufacturing, quality management, smart factories, intelligent logistics and equipment services.

By connecting research and development, supply chain, production, quality, equipment and marketing domains, KingStar ensures seamless collaboration and efficient coordination across the entire drinkware value chain. This approach supports the overall digital transformation and intelligent evolution of the drinkware manufacturing industry. The successful implementation of the smart and intelligent manufacturing strategy will not only enhance the competitiveness of KingStar in the market but also contribute to the broader goal of promoting sustainable development and innovation in the manufacturing sector.

As our team delved deeper into the production floor, we embarked on a comprehensive tour of the entire manufacturing facility. The application of 5G technology in the production of drinkware and food containers at KingStar left us all in awe, as we recognized the company‘s role in spearheading the digital transformation and upgrading of the stainless steel drinkware factory pushed by Industry 4.0.

Upon reaching the factory sample area, our members eagerly examined the various samples of thermal mugs on display. Some weighed them to gauge their heft, while others tested their materials for quality. At the same time, we listened to the KingStar manager explain the unique features and functions of each type of thermal mug, and we were also provided with informative materials detailing the production process. Throughout this experience, many of our employees couldn’t help but express their admiration for the intricate design and functionality that goes into creating such a seemingly simple product. It was truly eye-opening to see how much “hidden potential” can be found within a seemingly ordinary stainless steel water bottle.

Intelligentization is the future development direction. As a drinkware manufacturing industry, if the KingStar wants to maintain its core competitiveness and continuously provide customers with high-quality and high-performance products, it needs to constantly innovate in technology and upgrade products. With the continuous development of technologies such as artificial intelligence and the Internet of Things, Industry 4.0 has become a trend in various industries. In the drinkware manufacturing industry, Industry 4.0 can help enterprises improve production efficiency, reduce costs, enhance product quality and improve user experience.

Finally, the manager of KingStar said that the Industry 4.0 is an important milestone, but not the end. In the future, KingStar will continue to invest more resources and efforts to continuously promote the application and development of smart manufacturing and industry, providing customers with higher quality, efficient and intelligent drinkware and services. At the same time, KingStar will also strengthen cooperation with partners to jointly explore new business models and technological application scenarios, promoting the intelligentization process of the entire industry.